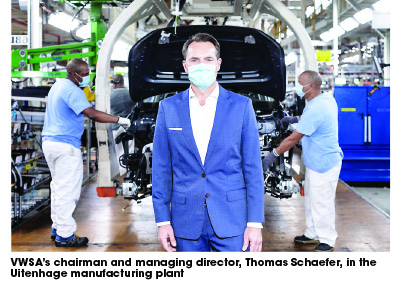

Following a gradual ramp-up of its local production, the Volkswagen Group South Africa (VWSA) plant in Uitenhage has resumed manufacturing operations.

In line with the regulations pertaining to Level 4 of lockdown, VWSA production was restarted recently, with essential employees returning to work in a phased approach.

This is coming after the group made its Port Elizabeth plant available as a temporary medical facility to assist local and provincial government in providing much-needed care to COVID-19 patients in Nelson Mandela Bay till March 2021.

The plant in Neave (Korsten, Port Elizabeth), which is currently not in use, is being converted to be used as an overflow medical facility. Once fully operational, the facility could accommodate up to 4,000 beds for patients diagnosed with the COVID-19 virus. This would also include high-acuity patients who require oxygenation.

The conversion of the 66,000m² building is the result of collaboration formed between VWSA, the Nelson Mandela Bay Business Chamber, the Nelson Mandela Bay Municipality and the Eastern Cape Department of Health.

The German Federal Ministry for Economic Cooperation and Development (BMZ) is providing funding of 5.2 million Euros to support the conversion of the plant as well as the procurement of protective gear (PPE). The facility is to be completed in phases and handed over to government as the need for medical care in the area develops.

VWSA is contributing R28 million to the project, in addition to project management for the conversion of the facility and management of the procurement of the critical PPE.

Following the resumption of operations in Uitenhage, the company has started exporting Polos to various markets, in addition to manufacturing Polos and Vivos for the local market. On-site employees are supported by colleagues who continue to work from home where this is possible.

Prior to the gradual ramp-up of production, a number of measures to combat COVID-19 were put in place at all VWSA sites. These measures form part of a 100-point plan implemented across the Volkswagen Group to ensure the health and safety of employees.

“Our essential services team ensured that the workplace was COVID-19 compliant before we officially restarted production in Uitenhage,” said Jens Bruecker, Production Director at VWSA. “Our 100-point plan is designed to ensure that all employees feel safe and good about their workplace, so we can manufacture and deliver vehicles without compromising our commitment to the wellbeing of our employees.”

“With dealerships being allowed to reopen on a phased basis, VWSA will again be able to meet the needs of its loyal local customer base,” said Mike Glendinning, VWSA’s sales and marketing director. “Our team has worked remotely during the lockdown to support dealerships in preparing to reopen, and to assist customers through our Customer Interaction Centre.

VWSA’s chairman and managing director, Thomas Schaefer, thanked the National Association of Automobile Manufacturers of South Africa for its assistance in lobbying with government for the automotive industry to be allowed to reopen. “The automotive industry has a crucial role to play in the local and national economy,” said Schaefer. “We are grateful that this role was acknowledged with the decision to let the industry operate and trade again.”

Credit: The Sun